9 things you can bring on a plane, but not a cruise ship

In:There are certain items that you can pack on a plane but are banned on a cruise ship.

Each mode of transportation comes with its own set of regulations, and your packing list might be different depending on how you're traveling.

Regarding what you can bring on a cruise ship, the rules differ from those of TSA and airlines.

If you're not careful, you could safely pass through airport security only to be stopped before boarding the cruise ship.

Any prohibited items you've packed will be confiscated, and not all of them are returned at the end of the cruise.

To prevent an embarrassing moment and the loss of your items, make sure that you're not bringing these 9 banned things.

Read more: How early should I pack for my cruise?

1. Your pet

If you're going on a cruise, your furry friend will have to stay home.

Airline regulations allow guests to bring small pets on planes, provided they fit inside a zippable carrier.

Most airlines also charge an additional fee for passengers with pets, usually between $100 and $200.

However, Royal Caribbean ships do not permit any pets on board, other than registered service animals.

Royal Caribbean allows assistance dogs onboard when pre-approved by government authorities and with proof of the proper documentation.

However, any pets will have to stay with friends, family, or a sitter.

2. Fresh food

TSA allows you to bring fresh food—such as eggs, meat, seafood, vegetables, and fruit—through security.

While meats must be packaged in ice, and you cannot always bring fresh vegetables, in general, TSA will allow you to pack a considerable meal.

While you may be able to bring a home-cooked meal on a plane, you cannot carry fresh food onto a cruise ship.

Royal Caribbean only allows dry, packaged snacks onboard, like cookies, chips, crackers, or energy bars. These packages must be sealed and non-perishable.

Any fresh food will be confiscated, so finish your leftovers before boarding!

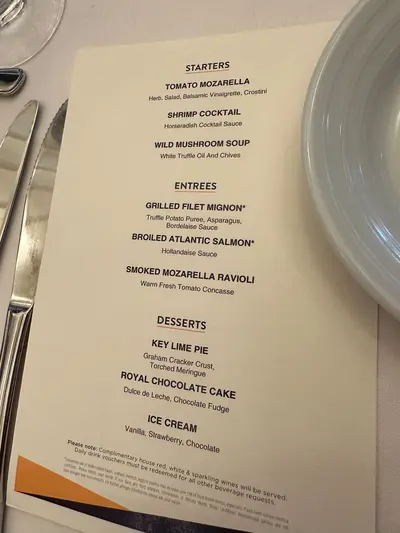

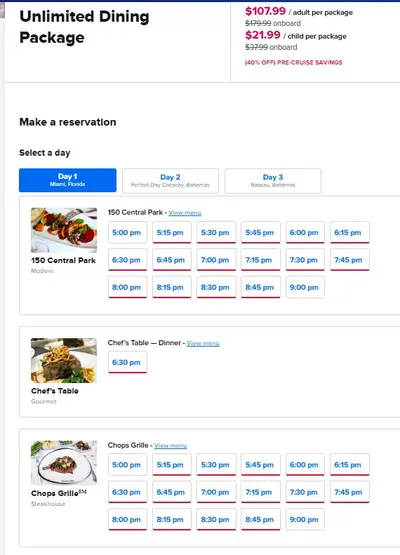

Plus, your cruise fare includes access to many great dining venues, so bringing food onboard is the least of your worries.

3. Hard liquor

According to TSA's requirements, you may pack any amount of an alcoholic beverage with 24% alcohol or less in a checked bag.

For alcoholic beverages with more than 24% percent (but less than 70%) alcohol, you're limited to 1.3 gallons (5 liters) per passenger in a checked bag, provided it is inside unopened retail packaging.

For a carry-on bag, you may bring miniature bottles that fit into a quart-sized Ziploc bag.

The requirements are quite different for cruising.

Although you can bring 1 bottle of wine per adult onto a cruise ship, you are not permitted to pack any hard liquor.

If you attempt to bring any hard liquor onboard on embarkation day, it will be confiscated.

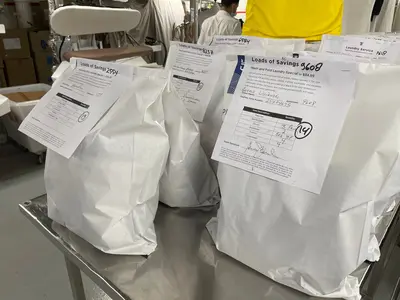

Whether you choose to purchase tequila in Mexico or rum in Jamaica, you can, however, purchase liquor at ports of call.

If you do purchase liquor as a souvenir, crew members will take it when you re-enter the ship. They will label and keep the alcohol for you until disembarkation day.

4. Candles

We all want a refreshing fragrance for the cruise ship stateroom or bathroom, but you won't be able to bring a candle on your cruise.

Airplanes permit you to pack solid candles in both checked and carry-on luggage.

Read more: 21 Cruise Cabin Essentials Everyone Should Pack

However, flammable items and heat-producing items are strictly prohibited on a cruise ship. This includes candles and incense.

Any homemade candle or local incense purchases will have to wait until you get home.

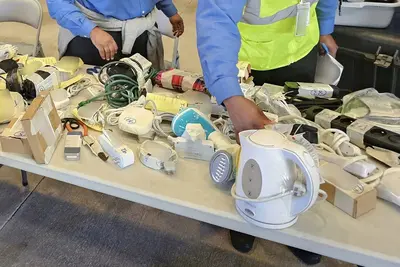

5. Clothing irons

Because of the high risk fires present on a cruise ship, you are not permitted to pack or use a clothing iron on a sailing.

They are considered heat-producing items and will be confiscated on embarkation day.

There aren't any irons present in Royal Caribbean staterooms, and self-service laundry isn't an option on a cruise.

However, you can send out laundry for crew members to wash, dry, press, or fold for you.

Laundry prices vary depending on the service you're looking for, but you can pay $35 for a wash and fold special, sending out a small bag of clothes.

Read more: We asked our readers what one thing they regretted packing for their cruise

6. Steamer

Much like irons, steamers are a heat-producing, prohibited item on a cruise ship.

If you're cringing at the idea of paying for laundry services, there are a few hacks our team likes to get the wrinkles out of your outfits.

You can use a Downy Wrinkle Release spray (this is an affiliate link, which costs you nothing extra to use but supports this site), which smooths out clothes once you hang to dry.

Packing the right material of clothing also helps; polyester, denim, cotton, and linen tend to wrinkle less.

7. Handcuffs

Whatever your reason for bringing handcuffs along, they won't be permitted on a cruise ship.

While TSA does allow handcuffs, cruise ships do not.

Royal Caribbean bans cruisers from bringing any items that are considered restraining devices, so that includes zip ties, leg cuffs, and leashes.

However, both modes of transportation permit other adult toys, so...

8. Heating pads

Preparing to manage any cramps, aches, or pains?

While TSA permits heating pads in both checked and carry-on baggage, Royal Caribbean does not.

Again, heating pads are considered heat-producing items and will be confiscated from your luggage.

Instead, consider packing Epsom salt or using a warm towel for any aches you experience on the cruise.

9. Electrical extension cord

TSA has no limitations on the kinds of extension cords you can pack on a flight.

However, standard extension cords—including surge protectors—are not allowed on cruise ships. They are a fire hazard.

Instead, you can purchase cruise-safe power strips, or bring along a USB outlet.

Read more: 115 item Ultimate Cruise Packing List (Printable PDF)